Understanding grain aeration

Aeration is primarily aimed at temperature control to prevent grain spoilage and insect infestation, allowing high moisture grain to be stored safely until it’s convenient to be dried, or allowing dry grain to be safely stored until it’s time to be shipped to market. This provides flexibility in storage options and allows more time to decide when to bring the crops to market.

The three keys to proper grain storage are:

-

Maintain low grain temperature levels

-

Maintain low grain moisture levels

-

Provide adequate and consistent airflow through the grain to enable either aeration or natural air drying

How does aeration work?

Airflow always takes the path of least resistance in a bin. To properly aerate stored grain, there must be a conduit that distributes the airflow generated by the fan throughout the bin, this being a full floor, Rocket® or horizontal tube.

Here are two key terms:

-

Airflow: The total amount of air being delivered to the grain mass, which is measured in cubic feet per minute through a bushel of grain (or CFM/bu).

-

Static Pressure: The resistance to airflow in the system. The aeration fan must generate enough airflow to overcome the static pressure in the bin. Factors that can affect the static pressure in the bin include:

-

The dimensions of the bin and the depth of the grain pile

-

The type of crop and its density

-

The type of aeration duct system in the bin, including the amount of open area in the ducts, the total contact area of the duct with the grain mass and how many corners the air must navigate to reach the grain mass

-

High static pressure scenarios can limit the fan options available, reduce the airflow potential and can affect the operation of supplemental heaters.

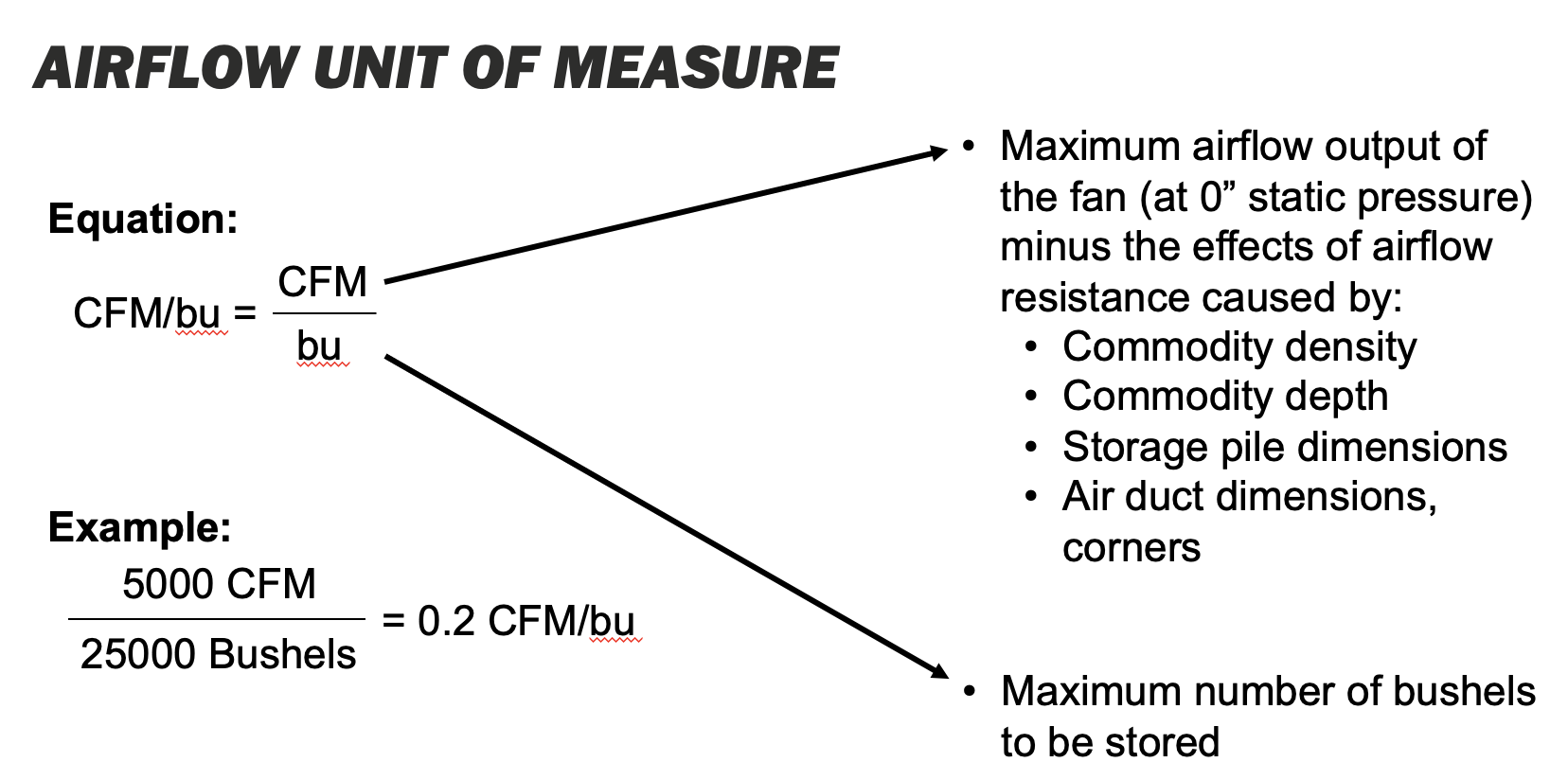

Airflow and static pressure tie into the standard unit of measure for grain aeration, which is CFM/bu. The equation to reach this value is simply the airflow CFM of the fan at a certain static pressure divided by the total number of stored bushels.

See the below equation on how to determine airflow unit of measure.

Grain moisture content

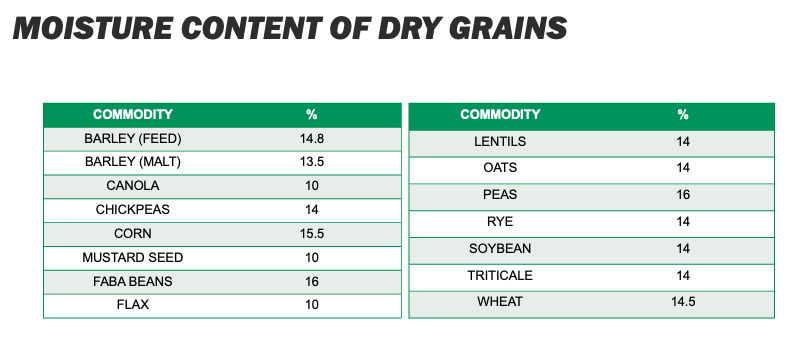

Each commodity has an optimal moisture content that will get the highest price at market. Aeration and natural air drying can help reduce, maintain and even (with limitations) increase the moisture content of the stored crop so that farmers can maximize their profits. A supplemental heater can help speed up the drying process by removing humidity from the incoming air, allowing the air to take on more moisture as it travels through the grain mass.

Optimal grain moisture content can vary by region. See the examples below.

Effective grain storage management

Deciding when to run aeration fans depends on the objectives you’re trying to achieve.

Objectives to consider:

-

Desired grain temperature

-

Desired grain moisture content

-

Uniformity of grain temperature and/or grain moisture content

Variable conditions to consider:

-

Ambient temperature

-

Ambient relative humidity

-

Equilibrium moisture content (EMC)

-

Grain temperature

-

Grain moisture content

Farmers may flip back and forth depending on the condition of the grain and where they’re at in the season. Maintaining uniformity of temperature and moisture within the bin should always be the goal.

AGI aeration

If you’re in the market for some new fans to protect your harvested grain, consider AGI aeration equipment. AGI fans and heaters are designed to efficiently deliver airflow inside the bin to maintain your grain quality. Our complete lineup of fans includes high speed centrifugal (3 to 40 HP), low speed centrifugal (5 to 50 HP), in-line centrifugal (3 to 15 HP) and Axial fans (3 to 15 HP).

Grain monitoring

Monitoring systems provide valuable data about the conditions in the bin and remove much of the guesswork. Modern systems will even alert users about dangerous storage conditions and some can automate the aeration process based on set parameters.

The AGI BinManager system can provide users with real-time oversight of the temperature, humidity and other conditions within the bin, allowing a quick response to hot spots and other conditions that may lead to spoilage.